How to effectively maintain injection mold

Details:

Injection mold is a kind of tool to produce plastic products; it is also a tool to give plastic products complete structure and precise size. Injection molding is a kind of processing method used in batch production of some complex parts, specifically, the melted plastic is injected into the mold cavity by high pressure injection molding machine, after cooling and curing, the products are obtained.

In the daily production of injection molds need effective maintenance, which can increase the life of the mold, thereby reducing the production cost of enterprises, then how to effectively maintain the injection mold?

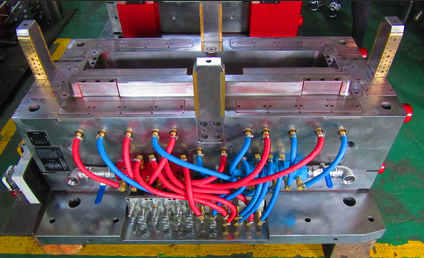

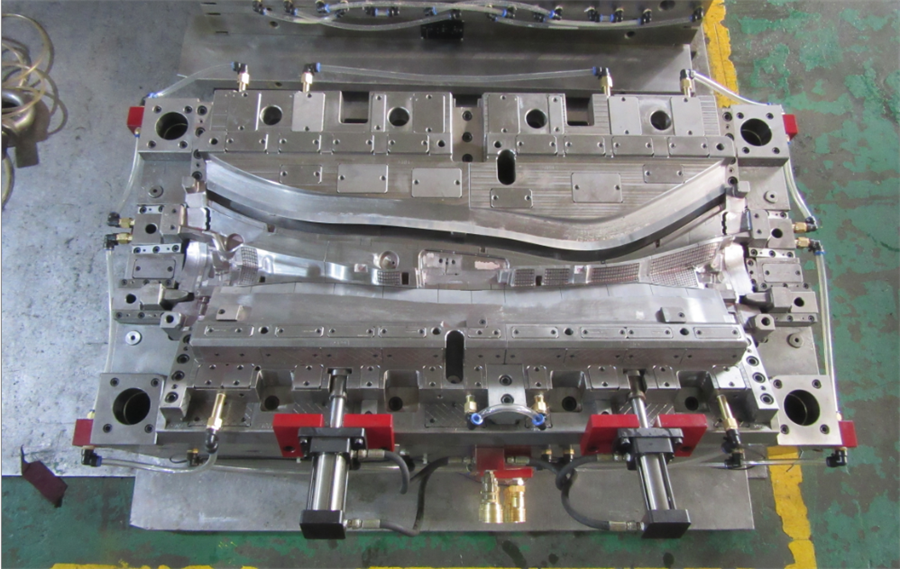

First of all, we should pay attention to the surface maintenance of the mold, that is, the appearance of maintenance, can not let the appearance of this mold damage, that is, can not let its corrosion, then choose a suitable, high-quality, professional rust-proof oil is particularly important. When the mold is finished, different methods should be adopted to carefully remove the residual injection molding according to different injection molding. Copper rod, copper wire and professional mold cleaner can be used to remove the residual injection molding and other deposits in the mold, and then air-dry. Disable iron wire and steel bars to clean the surface so as not to scratch the surface. If there are rust spots caused by corrosive injection molding, grinding machine should be used to polish, and sprayed with professional anti-rust oil, and then the mold placed in a dry, cool, dust-free storage.

Next is to regularly clean the injection mold, but also to ensure mold hygiene, for the production of products, clean and hygienic molds produced products better, and this is not to let molds be contaminated.

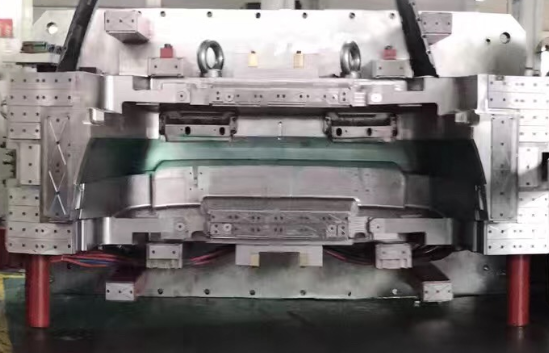

Thirdly, it is necessary to inspect the parts of the mold to see if the mold fails. The function of the ejecting and guiding parts is to ensure the opening and closing movement of the mold and the ejection of the plastic parts. If any part of the mold is stuck due to damage, it will lead to the shutdown of production. Therefore, the lubrication of the ejector pin and the guide post of the mold should be maintained frequently (the most suitable lubricant should be selected). And regularly check whether the thimble, guide post and other deformation and surface damage, once found, should be replaced in time; this avoids mold failure and the impact on product production.

Finally, the enterprise should arrange special personnel to carry out periodic statistical use, nursing, damage in the production of injection mold, in order to find problems in time and minimize the impact on production.